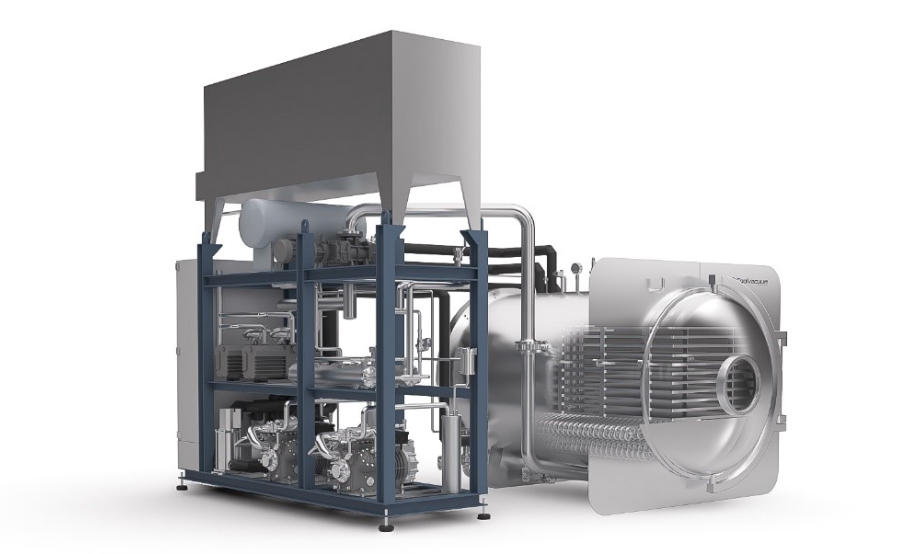

n the pharmaceutical industry, preserving and transporting biological products such as vaccines and biopharmaceuticals is a significant challenge. Freeze-drying technology has emerged as a solution, preserving products optimally and ensuring quality and efficacy. In Vietnam, Novalab proudly offers state-of-the-art freeze-drying systems that meet international standards, empowering pharmaceutical companies to enhance their competitiveness.

Freeze-drying technology is a process that removes water from a product at low temperatures and pressures, resulting in a porous solid. This process protects the biological structure and activity of the product while preventing the growth of microorganisms.

Novalab freeze-drying systems are designed with numerous advantages:

- High capacity: Meets the large-scale production needs of pharmaceutical companies.

- High precision: Ensures a consistent and stable freeze-drying process.

- Energy efficiency: Reduces energy consumption.

- User-friendly: Intuitive interface, easy to operate, and requires minimal technical expertise.

- Long lifespan: Durable materials and minimal maintenance requirements.

- Compliance with international standards: GMP, ISO.

Applications: Novalab freeze-drying systems are widely used in the production of:

- Vaccines: Preserving vaccines for extended periods, ensuring effective disease prevention.

- pharmaceuticals

Benefits: By using Novalab freeze-drying systems, pharmaceutical companies can:

- Enhance product quality: Ensure products meet the stringent requirements of the market.

- Increase productivity: Reduce production time and increase efficiency.

- Expand market reach: Access new markets with high-quality products.

- Ensure safety: Meet safety and hygiene standards.

Conclusion: Novalab freeze-drying systems offer a comprehensive solution for Vietnamese pharmaceutical companies, enabling them to enhance their competitiveness on the global market. With advanced features and a commitment to quality, Novalab systems contribute to producing high-quality pharmaceutical products that serve the health of the community.

Tiếng Việt

Tiếng Việt